If you want to install a metal roof on your home or commercial building, you might have encountered two popular metal roofing types: corrugated metal roofing systems and standing seam metal roofing systems. In this comprehensive guide, we will cover all the aspects of corrugated metal roofing panels and whether they are right for your project. Read this blog post through the end to know everything about corrugated metal roofs, including types, features, and how much they cost.

Understanding Corrugated Metal Roofing Systems

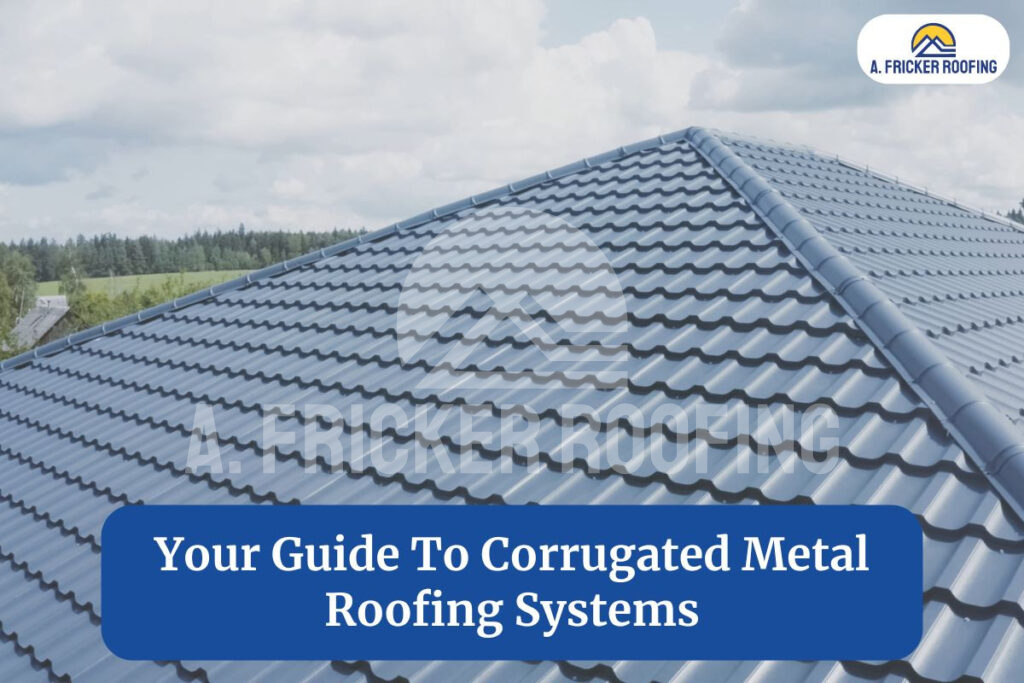

Corrugated metal roofing systems have been around for over 100 years, and many homeowners and roofers define them differently, thanks to the evaluation of metal roofing and the materials used. In general, corrugated metal roofing panels are famous for their wave-like appearance and industrial look.

While any metal roof with exposed fasteners is commonly referred to as a corrugated metal roof, experts distinguish corrugated metal panels for their distinctive rustic and wave-like appearance. This style of metal roof is often installed on commercial buildings, barns, or farmhouses for their more industrial look and distinctive appeal.

While corrugated metal roofs are traditionally the first choice of commercial building owners, they can also be installed in residential settings. Homeowners often prefer them for their minimalistic style and high energy efficiency. Corrugated metal panels are made using different types of metals, including steel, copper, aluminum, and zinc.

Related: Everything You Need To Know About Standing Seam Metal Roof

Types of Corrugated Metal Roof Panels

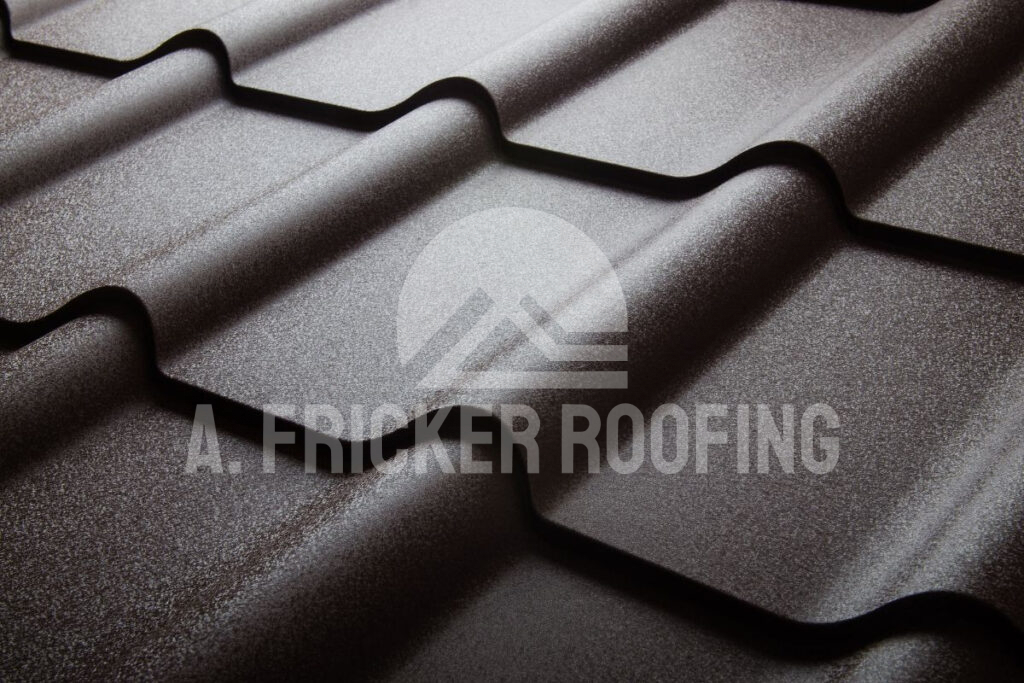

There are two common types of corrugated metal roof panels: ⅞ corrugated and ½ corrugated panels. These panels differ in the spacing and depth of their corrugations, leading to unique characteristics and applications. Let’s explore these two types of corrugated panels:

1. ⅞ Corrugated Metal Panels

The ⅞ corrugated panels are the most popular corrugated metal roof option. These metal roofing panels feature corrugations that are 7/8 inch deep. This larger corrugation size provides excellent strength and rigidity to the panels, making them ideal for use in industrial, commercial, and agricultural settings.

Another advantage of these corrugated panels is enhanced structural integrity and load-bearing capacity. They can withstand heavy loads and harsh weather conditions.

2. ½ Corrugated Panels

Another less popular yet simpler corrugated metal roof option is the ½ corrugated panel. In contrast to ⅞ metal panel, this panel profile features shallower corrugations at ½ inch deep. The smaller corrugation size gives these panels a sleek and modern look, making them suitable for contemporary architectural designs.

While ½ corrugated panels may not offer the same level of strength and load-bearing capacity as their larger counterparts, they are still durable and versatile. These panels are commonly used in residential roofing and siding projects, as well as in commercial and industrial applications where a more modern aesthetic is desired.

Also Read: 4 Metal Roofs That Look Like Shingles

Advantages of Corrugated Metal Roofing Systems

Corrugated metal roofs come with a number of advantages, including the following.

1. Durability

One of the most noticeable advantages of a corrugated metal roofing system is its durability. As seen in the ⅞ metal profile, the depth of corrugation and the spacing between each provide a more resilient and sturdy metal surface. Though lightweight, corrugated metal roofs can stand the test of time while also contributing to sustainability at the end of their lifespan, as they can often be recycled.

Unlike traditional roofing materials like asphalt shingles, metal is resistant to cracking, warping, and rotting. It can withstand harsh elements such as heavy rain, snow, hail, and strong winds.

2. Energy Efficiency

Regardless of the profile and size of the panels, corrugated metal roofs are energy efficient, thanks to their reflective surface and the materials used. The surface reflects a significant part of the sun and prevents heat transmission inside the building through panels, resulting in significant savings on energy bills. This allows your HVAC system to work less in summer and leads to a more comfortable indoor environment.

3. Versatility

Corrugated metal roofs, because of their light weight, offer solutions for both commercial and residential buildings. The ⅞ corrugated panels offer a more dimensional and rustic look on commercial buildings, while the ½ corrugated profiles, with their shallower corrugation, best suit residential buildings. In addition, these panels come with a wide range of color options, finishes, and materials to suit any architectural building.

Whether you prefer a classic farmhouse look or a sleek modern aesthetic, there’s a corrugated metal roof to suit your style.

Disadvantages of Corrugated Metal Roofs

Like any other roofing material, corrugated metal roofs have flaws that need to be considered before installation.

1. Potential Leaks

While corrugated metal roofs provide a durable and sturdy surface, their main problem is leaks, which occur mainly due to their installation method—exposed fastening.

Exposed fasteners on a metal roof require holes to be made in the panels so that they can be nailed to the roof deck. This installation method increases the chance of leaks. Though various techniques can be incorporated to lock and seal the holes, they sometimes prove to be ineffective, especially if the metal roof is old or when the panels are undergoing thermal expansion and contraction.

2. Rust And Corrosion

Corrugated metal roofs are no exception to rust and corrosion, any metal roof that is not properly maintained or painted and sealed can form rust and corrosion. This is mainly caused by constant exposure to rainwater, chemicals, and heat.

Also, the slope of your roof plays a significant role in this case. Water pooling on the roof due to insufficient slope for an extended period can cause the metal panels to corrode, potentially affecting the curb appeal and durability of your roof.

The Cost Of Installing A Corrugated Metal Roof

The cost of installing a corrugated metal roof depends on many factors, including:

1. Materials

The cost of corrugated metal panels can vary depending on the type of metal used (steel, aluminum, copper), the gauge or thickness of the panels, and any special finishes or metal roof coatings. On average, they can range from $3.50 to $6.50 per square foot

Additionally, depending on local building codes and climate considerations, you may need to install a metal roof underlayment or insulation beneath the roofing panels to provide additional protection and energy efficiency. The cost of underlayment and insulation materials can vary but adds to the overall project cost.

2. Installation Costs

The labor cost for installing a corrugated metal roofing system can vary depending on the complexity of the project, the skill level of the roofing contractor, and local labor rates. On average, labor costs range from $4 to $8 per square foot.

Moreover, if you’re replacing an existing roof, you’ll need to factor in the cost of removing and disposing of the old roofing materials. This can add to the overall labor cost of the project.

3. Total Cost

Overall, the total cost of installing a corrugated metal roofing system for an average-sized home (2,000-square feet) can range from $10,000 to $24,000 or more, depending on the factors mentioned above. It’s essential to obtain quotes from multiple roofing contractors and carefully review the scope of work and materials included to ensure an accurate estimate for your specific project.

Final Thoughts

While installing a corrugated metal roof may cost more upfront than some other roofing materials, its durability, longevity, and energy efficiency can provide long-term value and cost savings.

Make sure to consider the pros and cons of corrugated metal panels to decide whether you should install them. This will help you make an informed decision for the years to come. Additionally, proper installation by experienced professionals is crucial for maximizing the lifespan and performance of your corrugated metal roofing system.

Consult a professional roofer in your area for help with your roofing project.

Contact A. Fricker Roofing and Waterproofing In Tulsa, OK, For Your Metal Roof Installation

A. Fricker Roofing and Waterproofing is a leading roofing company in Tulsa, OK, specializing in premium roof installations, including metal roofs.

Installing a metal roof is a significant investment. If not done correctly initially, it can lead to many problems down the road, which can even cost you more. Hire a skilled, reputable roofing company, like A. Fricker Roofing and Waterproofing, so you never have to worry about your roof. Contact us today at (918) 402-7167 to consult our roofing professionals.