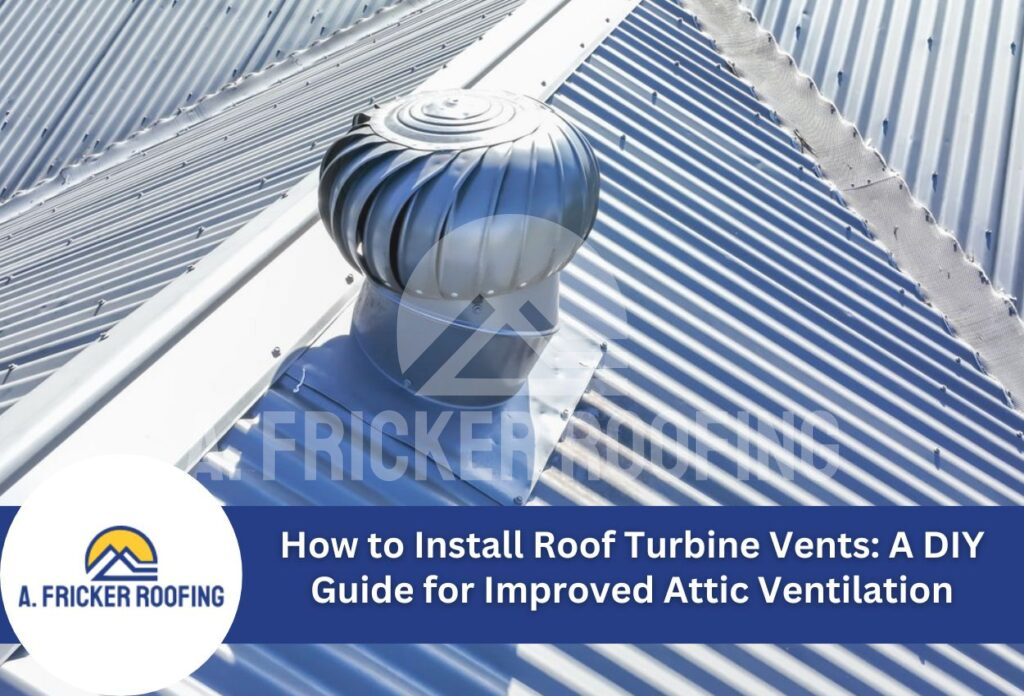

How to Install Roof Turbine Vents: A DIY Guide for Improved Attic Ventilation

Proper roof ventilation plays an important role in maintaining your home’s structural integrity and energy efficiency. Roof turbine vents are among the most effective solutions for Tulsa homeowners looking to improve attic airflow without relying on electrical power. These spinning vents harness natural wind power to pull hot, humid air from your attic space, helping prevent moisture damage, reducing cooling costs, and extending your roof’s lifespan.

The installation process involves selecting the right location, cutting an appropriate-sized hole, securing the base flashing properly under shingles, and ensuring the turbine is level and securely fastened. With basic roofing tools like a reciprocating saw, roofing nails, and sealant, most homeowners can complete this project in a few hours.

Installing roof turbine vents is a project that many homeowners can tackle themselves with the right tools and knowledge. While professional installation guarantees the best vent placement and warranty protection, a careful DIY approach can save on labor costs while still delivering excellent ventilation results.

Planning Your Turbine Vent Installation

Before climbing onto your roof to install turbine vents, proper planning is essential for the best outcome. In Tulsa’s climate, where summer heat can be intense, the general rule is one turbine vent per 150 to 300 square feet of attic space. However, consider your home’s specific characteristics. Homes with steep roofs or existing passive vents may need adjustments to this formula.

Start by measuring your attic’s square footage and inspecting existing ventilation. A balanced system requires sufficient intake vents (usually in soffits or eaves) to match your exhaust capacity. Without proper intake, even the best turbine vents won’t function effectively. For Tulsa homes, placing vents near the roof peak maximizes hot air extraction during our hot summers.

When deciding installation locations, figure out which way the wind typically blows through your neighborhood. Turbine vents work best when positioned to catch consistent airflow, spacing out multiple vents across the length of your roof for balanced ventilation. Avoid installing vents too close to chimneys, valleys, or areas where snow might drift in winter.

Use chalk to mark installation spots in order to align roof vents with your attic rafters for structural support. For typical Tulsa roofs with moderate pitches (4/12 to 8/12), positioning vents about two feet below the ridge provides excellent results while maintaining the curb appeal of your home.

Essential Tools and Materials for a Successful Installation

Gathering the right tools and materials before starting your roof turbine vent installation will save time and ensure quality results. For Tulsa homeowners tackling this project, having the proper equipment is important for both safety and effectiveness, especially considering Oklahoma’s ever-changing weather conditions.

For tools, you’ll need a circular saw or reciprocating saw with appropriate blades for cutting through roofing materials, a jigsaw for precision cutting, a utility knife, a hammer, a drill, a tape measure, a chalk line, and roofing nails (1¼-inch galvanized). You will also need a caulking gun for applying roofing cement and sealant. Don’t overlook safety equipment. A sturdy ladder, a fall protection harness, non-slip shoes, work gloves, safety glasses, and a dust mask will protect you during the installation process.

For materials, you’ll need the turbine vents themselves (aluminum or galvanized steel versions withstand Oklahoma’s severe weather best), roofing cement, a roof flashing kit, underlayment patches, and matching shingles for repairs. Select turbine vents with ball bearings rather than bushings for longer life in our climate. When choosing sealants, opt for high-quality silicone or polyurethane varieties that can endure Tulsa’s temperature extremes. Weather-resistant flashing is particularly important during Oklahoma’s rainy seasons to prevent leaks around your new installation. Having extra shingles on hand helps ensure you can properly finish the job with matching materials.

Step-by-Step Roof Turbine Vent Installation Process

Installing roof turbine vents requires precision and attention to detail to ensure proper function and prevent leaks. The process begins with careful preparation of your work area. Clear debris from the section of the roof where you’ll be installing the vent. For Tulsa homes with asphalt shingles, choose a day with moderate temperatures, as extremely hot weather can make shingles brittle and difficult to work with.

- Start by locating the rafters using a stud finder from inside your attic, marking their position to avoid cutting through structural supports

- Place the vent base flashing on your marked location and trace around it with chalk

- Using your reciprocating saw, carefully cut through the shingles and decking to create the vent opening

- Make the hole slightly smaller than your outline to ensure a snug fit for the vent base

- After cutting, slide the base flashing under the upper shingles, positioning it so water flows over the flashing, not underneath it

- Apply a generous bead of roofing cement around the underside of the flashing before securing it with roofing nails

- Place nails at the top edge and sides of the flashing, never at the bottom, where water could get in

- Once the base is secure, mount the turbine head and tighten all fasteners

- Finish by applying roofing cement over any exposed nail heads and along the edges of the flashing to create a weathertight seal that will stand up to Oklahoma’s unpredictable weather patterns

Weatherproofing and Finishing Touches

Proper weatherproofing is essential when installing roof turbine vents, especially in Tulsa, where we experience everything from intense summer storms to winter freezes. The key to a leak-free installation lies in thorough sealing techniques and careful attention to detail during the finishing stages.

Begin by applying a continuous bead of roofing cement under all flashing edges, creating a watertight seal between the flashing and shingles. When shingling around the vent, use the step-flashing method where each shingle course overlaps the previous flashing piece, directing water away from the vent opening. For enhanced protection in Tulsa’s heavy rainfall, add a secondary layer of sealant along the top and sides of the flashing, but leave the bottom unsealed to allow any trapped moisture to escape.

Inspect your installation by checking that shingles lie flat against the flashing without curled or raised edges. Test the turbine’s movement by gently spinning it, ensuring it rotates freely without wobbling or resistance. A properly installed turbine should spin smoothly with minimal wind. Check that all nails are properly sealed and no sharp edges from cut shingles are exposed. Examine the interior attic space below the installation for light penetration, which would indicate gaps needing additional sealing. Taking these extra steps ensures your new turbine vents will provide years of effective attic ventilation while protecting your home from Tulsa’s changing weather.

Maintenance and Troubleshooting Your Roof Turbine Vents

Keeping your roof turbine vents in the best working condition requires regular maintenance, especially in Oklahoma, where weather patterns can change dramatically throughout the year. Schedule inspections of your turbine vents at least 3 times a year, with special attention after severe storms. In spring, check for winter damage and clear any debris that may have accumulated. Summer maintenance should focus on ensuring free movement and proper lubrication to handle Tulsa’s intense heat. Fall inspections are crucial for removing leaves and preparing vents for winter weather.

When turbine vents begin making noise, the issue is typically related to worn bearings or loose components. Apply a silicone-based lubricant to the turbine’s moving parts to reduce squeaking and improve rotation. For vents that spin sluggishly or not at all, inspect for debris blockage or rust buildup on the bearings. Carefully remove any obstructions and clean the mechanism with a wire brush if necessary. Restricted spinning might also result from improper installation or vent damage, which may require adjusting the mounting or replacing damaged components.

Leaks around turbine vents often stem from deteriorated sealant or damaged flashing. Inspect the base flashing and reseal with quality roofing cement where needed. For persistent leaks, check if the vent has shifted position and reinstall it if necessary. With proper maintenance, your roof turbine vents can provide effective attic ventilation for many years, protecting your Tulsa home from moisture damage and helping maintain energy efficiency through all seasons.

When to Call a Professional Tulsa Roofer

While DIY roof turbine vent installation can be a rewarding project, certain situations call for professional expertise. If you notice persistent leaks despite your best sealing efforts, it’s time to contact a professional Tulsa roofer. Leaks can quickly lead to significant structural damage and mold growth, particularly during Oklahoma’s rainy seasons. Similarly, if you observe sagging around the installation area or hear unusual noises from your attic, these could indicate structural concerns that require immediate professional assessment.

Be aware that DIY may affect existing roof warranties. Many manufacturers void coverage if non-professionals modify the roofing system. If your roof is still under warranty, consulting with a Tulsa roofing contractor before installation can prevent expensive coverage issues down the road. Even after a successful DIY installation, scheduling a professional inspection offers valuable peace of mind. Experienced roofers can verify proper flashing integration, check for adequate ventilation balance, and ensure your new turbine vents complement your home’s overall roofing system.

Professional assessment also helps confirm that your ventilation solution addresses Tulsa’s specific climate challenges. Local roofing experts understand how proper attic airflow prevents ice dams in winter and reduces cooling costs during our hot summers. Their specialized equipment can measure actual airflow and identify any ventilation improvements needed to maximize your roof’s lifespan, potentially saving you significant money in the long term.

Expert Roof Turbine Vent Installation with A. Fricker Roofing & Waterproofing

If you’re considering installing roof turbine vents to improve your home’s attic ventilation, remember that professional installation can significantly enhance the vent’s efficiency and durability. At A. Fricker Roofing & Waterproofing, we specialize in ensuring your turbine vents are perfectly aligned with Tulsa’s unique climate. To guarantee a flawless installation and the best performance for your roof turbine vents, give us a call today at (918) 402-7167.