Galvalume Metal Roof: The Ultimate Guide For Cost, Colors, Installation & Comparisons

As a professional roofing company in Tulsa, we’ve installed about every roofing material out there. When a homeowner wants something strong, low-maintenance, and built to last, Galvalume is a great option.

This isn’t a trend. Galvalume steel has earned its reputation because it resists rust, reflects heat, and looks good on almost any home style. It’s durable, efficient, and, when installed correctly, can outlast most other roofs in its price range.

In this guide, we’ll get into detail about Galvalume metal roofs, their cost, where they perform best, and how they compare to other options like galvanized steel and aluminum.

What Is a Galvalume Metal Roof?

Galvalume is a type of steel roof coated with a mix of aluminum, zinc, and a small amount of silicon. That combination is what sets it apart. The aluminum gives it excellent corrosion resistance. The zinc offers sacrificial protection, meaning it takes damage instead of the steel. The silicon helps the coating stick and stay strong over time.

The result is a roof that lasts longer, resists rust better, and maintains its appearance far better than standard galvanized steel.

Galvalume was first developed in the 1970s by Bethlehem Steel. The roofing industry quickly caught on. Over the past few decades, Galvalume has become a go-to metal for residential and commercial roofs across the U.S.

Today, it’s used in everything from modern homes to agricultural buildings. It strikes a balance between being durable and low maintenance but not overpriced.

If you’re considering a metal roof, Galvalume is likely an option you’ve thought about. It’s strong, sleek, and engineered to last.

Galvalume Metal Roofing Types

One of Galvalume’s biggest advantages is its versatility. Whether you’re after something modern and sleek or more traditional, there’s a style that fits.

Standing Seam Galvalume Roof

This is the premium option most people consider when choosing a metal roof. Galvalume standing seam metal roof panels run vertically from ridge to eave, with hidden fasteners tucked beneath raised seams. This clean, uninterrupted design helps prevent leaks and reduces maintenance over time. It also pairs well with solar panels and modern architecture.

Corrugated and 5V Crimp Panels

These are the more traditional styles you’ll see on barns, sheds, and country homes, but they work just as well on residential roofs when done right.

- Corrugated Galvalume has a familiar wavy profile. It’s strong, affordable, and sheds water easily.

- 5V Crimp panels have subtle ribs and a vintage aesthetic. They’re popular in southern coastal homes and agricultural buildings.

Both styles use exposed fasteners, which makes them quicker to install and more budget-friendly. Just know that exposed screws may need occasional tightening or replacing over the years.

Galvalume Metal Shingles and Tiles

If you like the idea of metal but prefer a more traditional look, Galvalume shingles or stamped tiles could be the right fit. They’re made to mimic materials like slate, wood shakes, or clay tile and are installed in smaller sections like standard shingles. While not as common as panels, they offer solid durability, corrosion resistance, and added design flexibility if you prefer classic curb appeal.

Galvalume Metal Roof Colors & Finishes

Galvalume’s natural color is a smooth, matte silver. It reflects sunlight, helps reduce cooling costs, and develops a soft patina over time that prevents rusting in normal conditions. It’s a great option for homeowners who prefer a clean, modern style with low upkeep.

But Galvalume is also available in various factory-painted colors, including dark gray, black, green, and white. These finishes are made to resist fading, chalking, and harsh weather. White-painted Galvalume, in particular, is often used in hot climates for its cooling benefits.

While Galvalume can be painted, a pre-painted metal roof may offer additional color options. That said, Galvalume holds its natural finish longer and is often more affordable when not painted.

Some manufacturers also offer textured or low-gloss finishes. These reduce glare and help hide minor imperfections like oil canning. Whether you want your roof to blend in or stand out, there’s a Galvalume finish that fits your home’s look.

Can You Paint Galvalume Metal Roofing Panels?

Yes, you can paint a Galvalume metal roof, but bare panels need to be primed first with a product made for metal. Many homeowners opt for factory-painted Galvalume instead, which comes with a baked-on finish that’s more durable and often backed by a warranty. Repainting later is possible, but it won’t offer the same long-term performance.

Galvalume Metal Roofing Price Breakdown

Investing in a Galvalume metal roof involves understanding both material and installation costs. On average, homeowners can expect to pay between $1.00 and $4.50 per square foot for Galvalume roofing materials. For a typical 1,000-square-foot roof, this translates to $1,000 to $4,500 for materials alone.

Installation costs are based on roof complexity, regional labor rates, and contractor expertise. Labor costs typically start around $2 per square foot but may go up to over $10 per square foot. The total installed cost for a Galvalume metal roof typically falls between $3 and $14.50 per square foot and higher, depending on the factors mentioned above including panel style and color.

Prices can also fluctuate based on location, roof design, and additional features such as insulation or custom finishes. While the initial investment in a Galvalume roof may be higher than traditional asphalt shingles, its durability and longevity often result in cost savings over time.

It’s recommended to talk to a local roofing contractor for a more accurate metal roofing project estimate. They can provide detailed quotes that consider your requirements and regional pricing trends.

How to Install Galvalume Metal Roofing System

When you install a Galvalume metal roof, you’re building more than just a covering. You’re creating a system that has to perform under pressure from rain, wind, sun, and time. Success comes down to how well the surface is prepped, how precisely the panels are laid, and how every seam and fastener is handled.

Prepare the Surface

The first step is making sure the surface beneath the roof is solid. Galvalume should be installed over a clean deck. A synthetic underlayment is then added to prevent friction between the deck and the underside of the metal. This layer also adds moisture protection and helps extend the roof’s life. While it may be tempting to install the Galvalume metal roof over shingles, this is not recommended and can lead to significant problems over time.

Install the Panels

After prepping the surface, panels are measured, cut, and laid out in alignment with the roof slope. Fasteners are installed according to the profile being used. With exposed fastener systems, screws go through the raised ribs of the panels. Standing seam systems use hidden fasteners that are tucked beneath interlocking seams.

Accuracy is critical. Each fastener must be placed with the right pressure and spacing. Over-tightening can deform the panel or damage the sealing washer, leading to potential leaks.

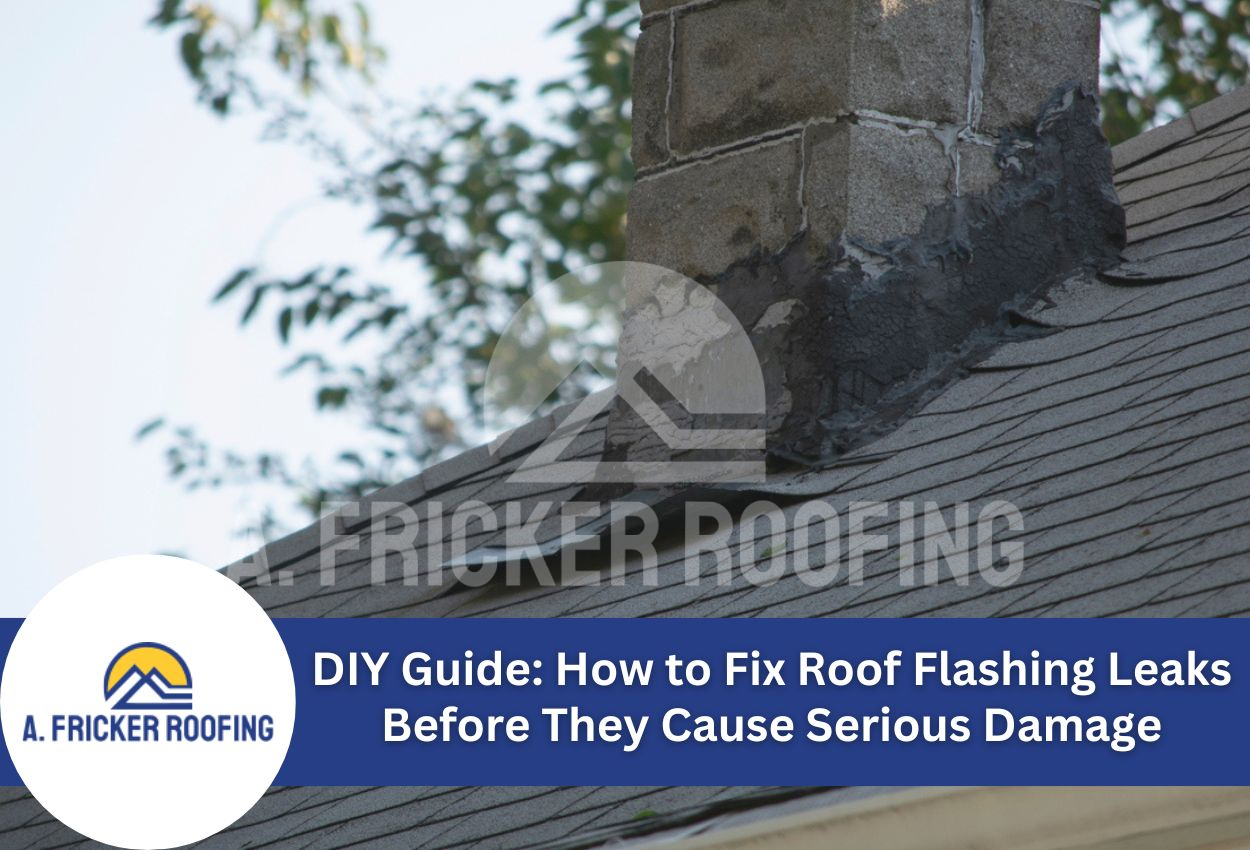

Flashing and Waterproofing

Once the panels are secured, flashing is added around valleys, chimneys, walls, and roof penetrations. These components direct water away from joints and edges where leaks form. Foam closures, sealants, and butyl tape are installed at ridges, eaves, and panel ends to keep out wind, rain, and pests. These small details keep a metal roof watertight for the long haul.

Professional vs. DIY Installation

Experienced DIYers may be able to install a Galvalume roofing system, but it’s not a weekend project. It requires specific tools, the ability to work at height, and attention to detail. Misaligned panels or incorrect fastener placement can compromise the roof’s performance. Hiring a qualified metal roofing contractor is highly recommended if you’re unfamiliar with metal roofing or dealing with a complex roof layout. Proper installation means fewer problems, better performance, and a cleaner finish that will last decades.

Maintaining & Cleaning a Galvalume Metal Roof

Galvalume roofs are low-maintenance but still need occasional care to perform at their best. Knowing how to properly clean a Galvalume metal roof helps preserve its finish and extend its lifespan.

Use a soft-bristle brush, mild soap, and water to clean the surface. For tougher spots, like sap or bird droppings, let the soap sit briefly before rinsing with clean water. Pressure washers should not be used because the strong spray can loosen fasteners and force water in between the panels.

Avoid chemicals, bleach, or abrasive tools. These can damage the protective coating on bare Galvalume or painted panels. Stick to manufacturer-approved cleaners and always rinse thoroughly.

Basic metal roof maintenance includes clearing leaves, checking fasteners, and inspecting flashing once or twice a year. With regular upkeep, a Galvalume roof can last 40 to 70 years. Many systems come with 25 to 50-year warranties, but keeping that warranty valid depends on following care guidelines.

Drawbacks of Galvalume Metal Roofs: Common Issues to Know

Galvalume metal roofs are known for their strength and longevity, but like any material, they have a few potential downsides worth noting.

Oil Canning

This is a cosmetic issue where the flat sections of metal panels appear slightly wavy. It doesn’t affect the roof’s performance or lifespan, but some homeowners find it distracting. Choosing thicker panels and striated finishes and working with an experienced installer can help reduce it.

Dents and Impact Damage

Galvalume is strong, but not dent-proof. Large hail, falling branches, or even dropped tools can leave a mark on thinner gauge panels. Standing seam systems made from heavier materials offer better protection.

Corrosion from Poor Handling

While Galvalume resists rust better than galvanized steel, it can still corrode if stored improperly before installation. Panels stacked in standing water or exposed to high moisture can oxidize. Once installed, trapped debris and unsealed fasteners can also create trouble spots over time. Good drainage, proper installation, and occasional maintenance go a long way in preventing this.

Galvalume vs. Galvanized vs. Aluminum: What’s the Difference?

If you’re looking at a metal roof, you’ll often hear these three names: Galvalume, galvanized steel, and aluminum. They all have their place, but they’re not created equal.

Galvalume vs. Galvanized Steel

Both are steel at their core but the main difference is in the coating.

- Galvanized steel is coated with pure zinc. It protects well but can break down over time in areas with heavy rain or high humidity.

- Galvalume is coated with aluminum, zinc, and silicon. It lasts longer, fights rust better, and keeps its clean look longer than galvanized.

Galvanized steel is still used for barns because of its affordability and strength. But for residential roofs, Galvalume has mostly taken over, and for good reason.

Galvalume vs. Aluminum

Aluminum is its own metal and it has one huge advantage: it doesn’t rust. That’s why aluminum is the top choice for coastal homes. Salt spray that would eat through Galvalume over time won’t touch aluminum.

However, aluminum is:

- More expensive (typically 20% to 30% more)

- Softer (can dent more easily from hail)

- Prone to more thermal movement, which can cause oil canning if not installed correctly

Aluminum is a solid pick if you’re near the ocean or want a rust-proof roof. Otherwise, Galvalume offers a better balance of durability and price for most inland homeowners.

Is Galvalume Right for You? Final Thoughts

If you’re looking for a roof that’s strong, low-maintenance, and built to last, Galvalume is a good option. It gives you the durability of metal without the high price of copper or aluminum, and it performs especially well in hot Oklahoma summers.

That aluminum-zinc coating reflects heat, resists rust, and stands up to storms without demanding constant upkeep. For added protection, Galvalume Plus metal roofs come with a factory-applied acrylic finish that helps guard against scuffs, dirt, and stains, which is ideal for exposed fastener systems.

Galvalume metal roofing works best for homeowners who live inland and want a clean, modern look that holds up over time. Whether you choose standing seam, corrugated panels, or metal shingles, Galvalume fits a range of home styles and budgets. It’s especially perfect if you plan to stay in your home for years to come.

If you’re near the coast, aluminum may be worth considering, since it’s completely rust-proof in salt air. But for most homes here in Oklahoma, Galvalume strikes the perfect balance between cost, performance, and curb appeal. If you’re not sure what’s best for your home, talk to a local roofer who knows this material inside and out. We’ll help you make the right call.

Galvalume Metal Roofing Installation in Tulsa, OK

If you’re in the Tulsa area and considering a metal roof, talk to the team at A. Fricker Roofing & Waterproofing. We’ve installed Galvalume on homes across Oklahoma, and know what works in our climate, from panel profiles to coatings to the smallest flashing detail. Whether you’re building a new or replacing an old roof, we’ll walk you through the options, give you straight answers, and get the job done right.Ready to get started? Reach out today for a free estimate and expert guidance on Galvalume or any other metal roofing services. Call us at (918) 402-7167.