Key Points:

- Proactive ballast roof maintenance is important for extending the lifespan of a roof, preventing expensive water damage, and ensuring the best possible performance.

- Regularly inspect for ballast displacement, membrane issues, and clear drainage systems. Redistribute stones to maintain even coverage and prevent water pooling.

- Quickly address minor membrane repairs, but consult professionals for complex issues or extensive damage. This ensures proper long-term solutions and prevents escalation.

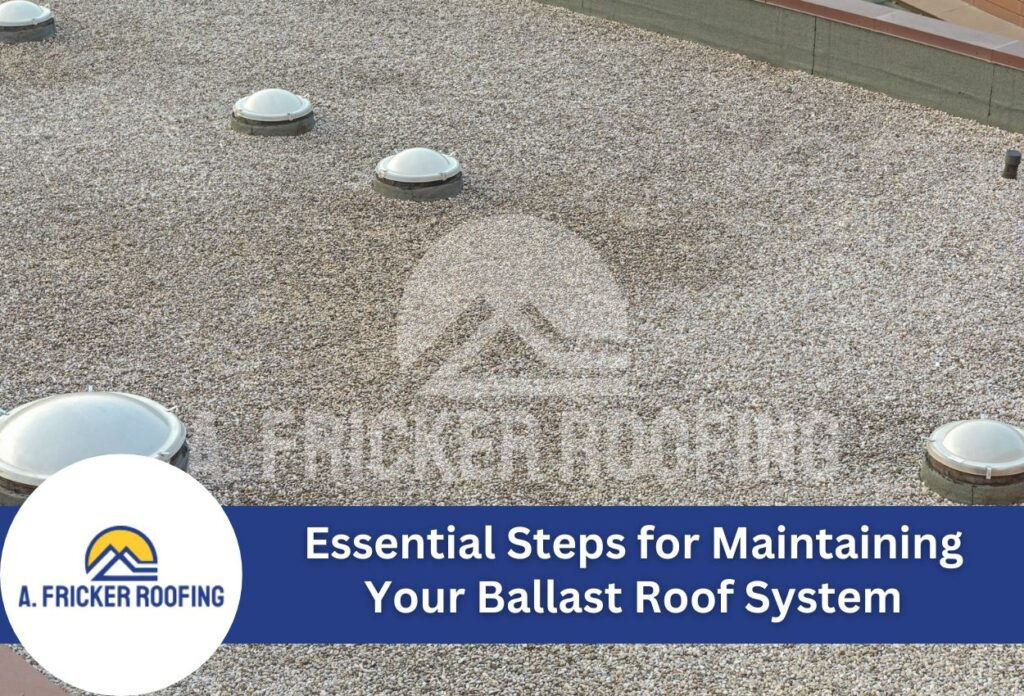

Ballast roof systems require consistent maintenance to protect commercial properties from water damage and structural deterioration. These single-ply membrane roofs, weighted down with gravel, pavers, or other materials, present unique maintenance challenges that property managers must address proactively. Without proper ballast roof maintenance, membrane punctures, displaced materials, and drainage issues can lead to expensive repairs and premature roof replacement.

Common maintenance tasks include checking the membrane’s structural integrity, ensuring proper drainage, repositioning displaced ballast materials, and removing debris that accumulates around drains and roof edges. Commercial roof ballast systems typically last 15 to 20 years when maintained correctly, making routine care essential for maximizing a return on investment.

Effective ballast roof repair addresses small membrane tears, reseals gaps, and maintains proper water flow across the roof’s surface. Property owners who implement regular maintenance schedules can avoid expensive emergency repairs and extend the functional lifespan of their roof system.

Regular Inspection Techniques for Early Problem Detection

Effective ballast roof inspection requires systematic examination of membrane surfaces, ballast distribution patterns, and potential trouble areas. Begin inspections by checking perimeter edges where wind uplift commonly displaces ballast materials, exposing the underlying membrane to UV damage and punctures. Examine areas around roof gaps, HVAC units, and drainage components where ballast accumulation often creates pooling water conditions.

Seasonal inspection checklists should document how much of the membrane is visible, noting areas where ballast has shifted or thinned. Look for torn or lifted membrane sections, particularly near roof equipment and high-traffic zones. Commercial roof ballast systems require different inspection approaches depending on weather conditions, with spring assessments focusing on winter storm damage and fall evaluations preparing for harsh weather ahead.

Document findings with photographs and written reports to track condition changes over time. This documentation is valuable for ballast roof repair planning and warranty claims. Pay special attention to drainage function, as blocked drains lead to water accumulation that accelerates membrane deterioration and creates structural concerns that compromise the entire roofing system’s performance.

Proper Ballast Management and Redistribution

Maintaining even ballast coverage requires an assessment of stone distribution across the entire surface of the roof. Storms, thermal cycling, and foot traffic commonly cause ballast materials to migrate toward the edge of the roof, drains, and low-lying areas. These displacement patterns create exposed membrane sections vulnerable to UV deterioration and punctures, while excessive accumulation in other zones can stress the underlying structure.

Effective ballast roof maintenance involves carefully redistributing displaced stones using proper techniques that protect the membrane’s structural integrity. Workers should wear soft-soled shoes and avoid dragging tools across exposed membrane surfaces during a repair. When adding new ballast materials, ensure compatibility with existing stones regarding size, weight, and composition to maintain uniform coverage and drainage characteristics.

Safe ballast redistribution requires identifying membrane condition before moving stones, as damaged areas need to be repaired before redistribution begins. Commercial roof ballast systems perform the best when stones maintain consistent depth across all roof areas, typically requiring annual redistribution to counteract natural settling and weather-related displacement patterns that occur throughout normal building operations.

Membrane Protection and Care Strategies

Protecting the membrane’s structural integrity beneath ballast stones requires specialized inspection methods. When examining commercial roof ballast systems, workers must remove small sections of ballast material to expose underlying membrane areas without disturbing the entire protective layer. Use gentle sweeping motions to clear stones from inspection zones, creating temporary access paths that minimize membrane exposure time.

During ballast roof inspection activities, look for early warning signs, including membrane discoloration, surface cracking, or small punctures that indicate deterioration. Bubbling or raised areas suggest moisture has gone beneath the membrane, while brittle or chalky surfaces indicate UV damage from inadequate coverage. Document the membrane’s condition with detailed notes and photographs before replacing protective ballast materials over inspected areas.

Preventive ballast roof membrane care includes maintaining proper stone coverage depth and removing sharp debris that could puncture the membrane during thermal expansion cycles. Membrane assessments should be scheduled during moderate weather conditions when materials remain stable and workable. Quickly repairing minor issues prevent leaks that lead to extensive structural damage and expensive emergency repairs throughout the building’s interior.

Drainage System Maintenance and Debris Removal

Properly functioning drainage systems remain critical for ballast roof maintenance success, as clogged drains and scuppers cause water pooling that accelerates membrane deterioration. Ballast stones naturally migrate toward drainage areas during storms, creating blockages that prevent proper water drainage. Removing accumulated stones from drain baskets and scupper openings prevents backup conditions that can stress the entire roofing system.

Organic debris, including leaves, seeds, and other plant matter, combines with ballast materials to form dense blockages around drains. These accumulations trap moisture against the membrane surface and create ideal conditions for vegetation growth that can puncture protective layers. Removing debris using soft brushes and vacuum equipment protects the structural integrity of the membrane while restoring proper water flow patterns across the roof’s surface.

Seasonal cleaning schedules should coincide with peak debris accumulation periods, typically following autumn leaf drop and spring storm seasons. Commercial roof ballast systems require careful debris extraction techniques that avoid disturbing surrounding ballast coverage. During ballast roof inspections, document drainage performance and plan ballast roof repair work to address any structural issues affecting water removal before problems arise.

Common Repair Procedures and When to Act

Successful roof maintenance depends on addressing problems quickly through proven repair procedures that prevent minor issues from becoming major failures. Small membrane punctures require immediate attention using compatible patching materials and proper surface preparation techniques. Clean the affected area thoroughly, removing all ballast stones and debris before applying membrane patches that go past the damaged area.

Ballast displacement issues often mean there are underlying problems, including inadequate edge flashing or structural movement that requires professional evaluation. Teams can safely redistribute small amounts of displaced ballast materials, but extensive migration patterns indicate systemic issues requiring contractor intervention. Commercial roof ballast systems experiencing repeated displacement problems need an assessment to identify the root causes.

Flashing repairs around gaps and roof edges require specialized knowledge of membrane compatibility and weatherproofing techniques. While property managers can perform basic cleaning and minor ballast adjustments, any work involving membrane cutting, adhesive application, or structural modifications should involve qualified roofing professionals.

Long-term Performance Changes and Professional Support

Successful ballast roof maintenance extends beyond routine inspections and immediate repairs to encompass long-term planning and strategic professional partnerships. Developing a proactive maintenance schedule requires establishing annual budgets for anticipated ballast roof repair needs while identifying opportunities for system improvements that enhance overall performance. Property managers should track maintenance costs and roof condition trends to predict when major interventions become necessary.

Working with experienced roofing contractors ensures complex ballast roof inspection tasks and membrane repairs receive proper attention using industry-approved techniques and materials. Professional contractors bring specialized equipment and expertise for challenging projects, including ballast material redistribution and drainage system modifications. Establishing ongoing relationships with qualified contractors provides priority service access during emergencies and competitive pricing for planned maintenance activities.

Commercial roof ballast systems benefit from periodic professional assessments that evaluate the system’s overall performance and identify upgrade opportunities. These evaluations consider factors including building use changes, local weather patterns, and evolving roofing technology. Strategic ballast roof membrane care planning incorporates both immediate maintenance needs and long-term system enhancements that maximize the roof’s lifespan while controlling the total cost of ownership over the building’s operational life.

Expert Ballast Roof Maintenance Services in Tulsa

If you manage a commercial property, you know that maintaining your ballast roofing system is important for the longevity and safety of your building. At A. Fricker Roofing and Waterproofing, we specialize in providing ballast roof maintenance that ensures your roof remains in top condition, preventing expensive damage and extending its lifespan.

Whether it’s performing detailed inspections, managing ballast stones, or ensuring your drainage systems are clear of debris, our team has the expertise to handle all aspects of ballast roof care. Don’t wait for small issues to become major problems. Proactive maintenance is key to saving on future repairs.

Ready to get the most out of your roof? Contact A. Fricker Roofing and Waterproofing today at (918) 402-7167 to schedule a consultation and ensure your roof is maintained by the best in the business.